Warehouse Heating For Large UK Distributor

The Challenge

A large well known distribution company, based in Essex, came to Celsius Hire with an issue. Their warehouse space was too cold every winter for teams to work. After multiple surveys it was deemed that installing a permanent warehouse heating system within the space was not feasible. They had rising concerns with multiple staff complaints every year and were conscious the temperatures were affecting overall productivity.

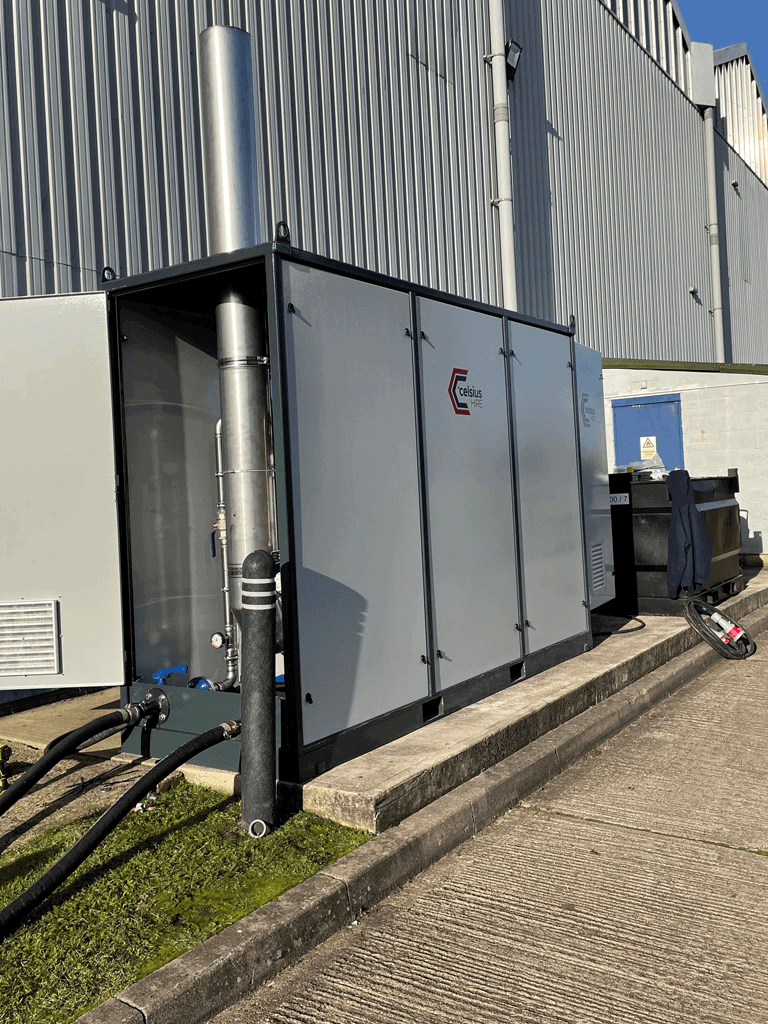

The warehouse was over 75,000 square foot, requiring a huge amount of heating to keep the space warm. With an absence of sufficient gas or electrical supplies, the heating system would need to be oil fired. Our challenge was to design a system that took the edge off, and spot heated, certain areas within the space. This would bring the temporary warehouse heating system within budgetary constraints, whilst also keeping staff happy and alleviating the client’s concerns.

The Solution

Following our preliminary discussions, we carried out a site survey was undertaken. This determined locations of the temporary plant within, and external to the warehouse.

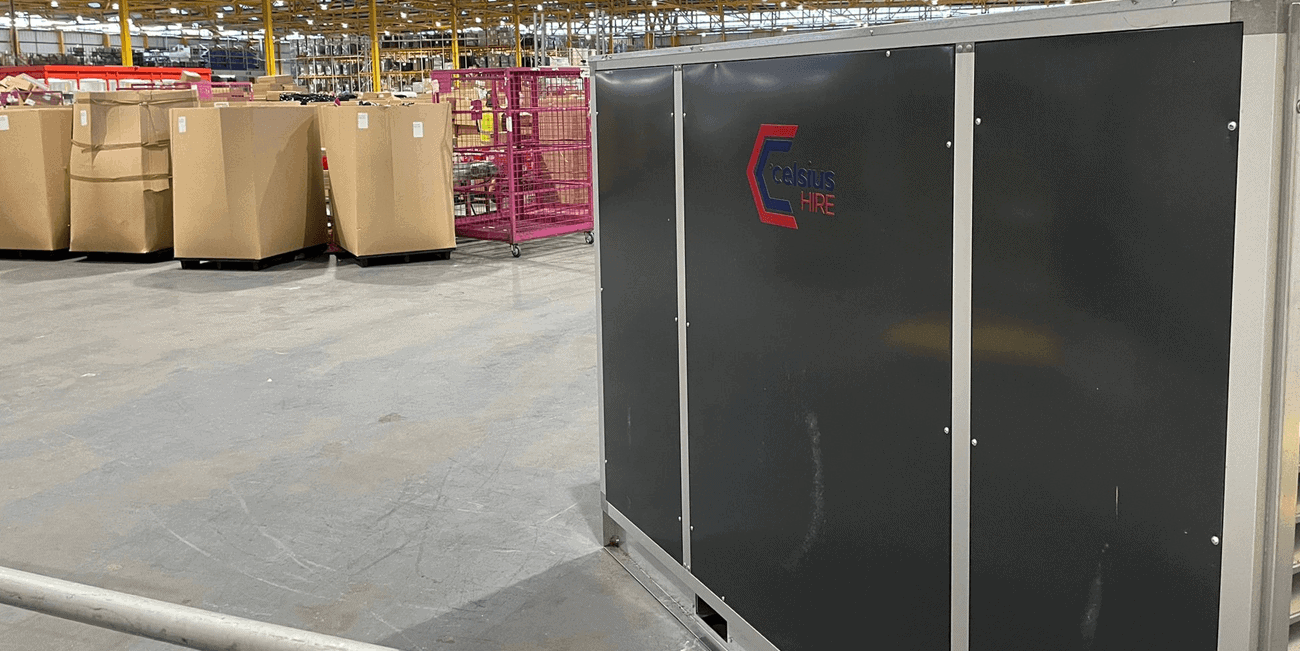

We agreed that the best solution to provide the most efficient heating within the area would be two re-circulating Air Handling units located inside the warehouse space, providing a high volume of warm air to the two packing areas of the warehouse (where the staff would do their jobs stood still). Each AHU connected to an externally located oil fired Boiler, using flexible rubber hoses. We determined a hose route between each Boiler and AHU. Taking in mind fire exit routes and trying to run at height where possible to avoid disruption to the processes for the staff.

The client agreed to install power supplies for all of our equipment, along with cutting of holes in the cladding to enable the hoses to go between the plant.

Warehouse Heating Equipment used:

The Result

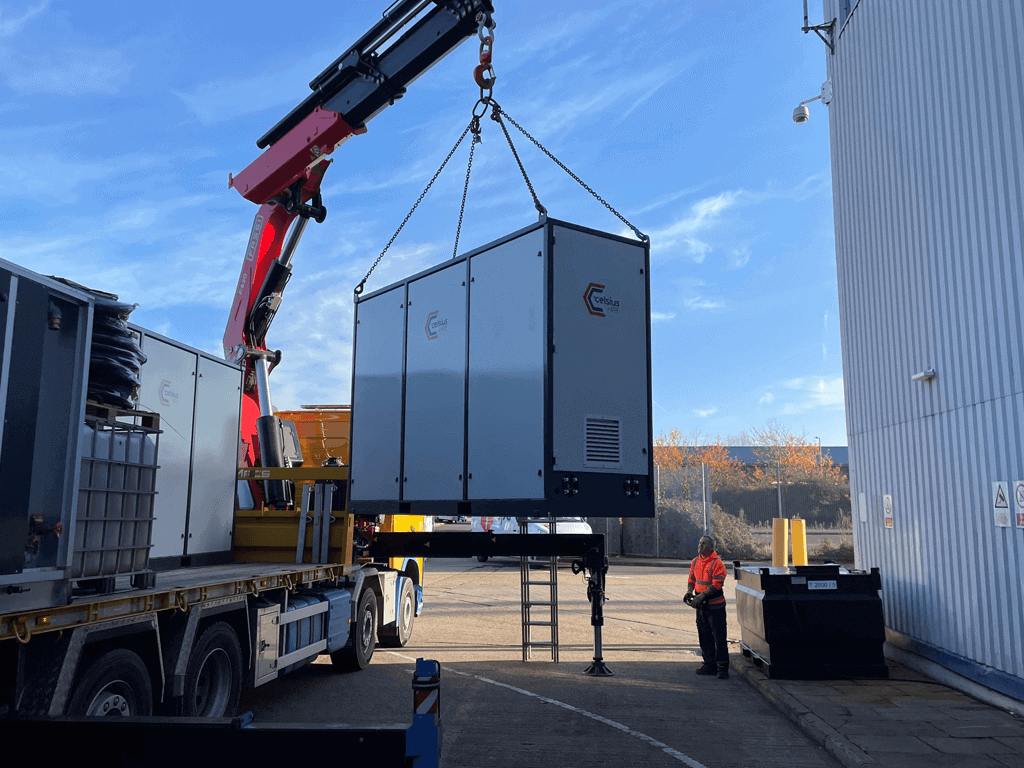

To achieve the warehouse heating solution we organised delivery at a time where the loading bay areas were the most quiet. This was important to ensure we did not disrupt operations when unloading the equipment via HIAB HGV.

The system we delivered was, installed and commissioned over a period of 2 days. Creating a fully functioning temporary warehouse heating system. Therefore, we were able to provide temperatures into the warehouse that the client had never been able to achieve prior.

Jake Revell, Director, commented;

“We often hear that installation of permanent systems are not feasible for many large scale warehouse heating, either due to budgetary restraints or lack of supporting infrastructure available to support the sheer amount of energy required to heat/cool such a space. When this client approached us it was clear that to secure the business we needed to work with them to provide a solution that solved their issues. But without going over the top and making it financially unsuitable. Luckily, we succeeded and looking forward to working with this customer in the winter seasons to come”